GRANICAP

For over 40 years, GRANICAP has been building solid partnerships and evolving alongside the sustainable development of Brazilian mining, serving the market with high-quality rocks and creating opportunities for people's fulfillment.

Through excellent work, in Colatina (ES), the company operates one of the most productive black granite deposits in Brazil, extracting and selling raw blocks to the global market.

Over the years, this work has boosted the dynamics of mining, resulting in the growth of the GRANICAP family, which today has more than 160 professionals, in addition to a large number of clients, partners and associates, generating wealth for the country and social well-being for the community.

By acquiring essential supplies and services for its operation, the mining company heats up the market monthly, allocating significant resources to more than 200 companies, of which around 100 are from Espírito Santo, Colatina, neighboring municipalities and urban center of Vitória.

In taxes and contributions collected from granite extraction activities, GRANICAP is today one of the most significant companies in the sector in Espirito Santo, occupying a prominent position among rock mining companies in Brazil.

Granicap's professional team

Know our work

fundamentals of our work

Protection of human life

OPPORTUNITIES FOR PERSONAL FULFILLMENT

Partnership and COOPERATION

Sustainable development

QUARRY BAUNILHA

In the Baunilha deposit, municipality of Colatina (ES), 100 km from Vitória, capital of Espírito Santo, around 4,000 m3 of black granite blocks are moved monthly, thanks to the good geological quality of the deposit, rigorous selection of rocks, professionalization administration, and also to the work of highly qualified operators of heavy machines and diamond wire with the support of a well-trained back-office team.

The company guarantees volume, fast delivery, continuity of supply and excellent use, since the final product is delivered in a perfect square, with all sides cut with diamond wire, in the ideal format for looms, allowing savings in subsequent stages: in shipping, cutting and finishing assembly of the pieces in industries and marble shops.

To achieve maximum quality in the operation of the Baunilha deposit, GRANICAP seeks constant improvement, adding to its team of professionals, some consultants prepared to offer high-level technical support in all areas, especially control, mining engineering, environment, occupational safety and health.

Our production process is carried out in full compliance with current Brazilian standards in mining, occupational safety, environment and cargo transportation.

sustainability

The main guideline of GRANICAP's environmental policy consists of operating the deposit with all the controls required for its production process, fully complying with current regulations and the conditions of the Operating Licenses, in order to guarantee a sustainable enterprise.

Today, environmental compensation areas are maintained and fenced by the company in Vanilha with periodic plantings of seedlings of native species acquired from the GAROZI nursery, which has allowed the protection of springs and created the necessary conditions for the consolidation and reinvigoration of these green areas of local wildlife.

With the expansion of the licensing polygonals in the new environmental licenses, the company is carrying out strategic mineral and environmental planning for the next 10 years, including investments in new compensation areas and preservation projects of endangered Atlantic Forest animal species, focusing on the Rio Doce Basin region.

Work Safety

GRANICAP is aware that its greatest asset is human capital and seeks daily to create and maintain a healthy working environment, with physical and psychological safety for everyone.

To this end, it invests in specialized engineering consultancy, which guides, supervises and develops the Internal Occupational Safety and Medicine Program, through SESMT. It also seeks to qualify its Human Resources professionals to improve the management and training of people, aiming for efficient performance and also professional fulfillment.

Today, internal programs are underway to encourage good risk control practices at work, such as the Annual Training and Qualification Plan, Monthly Equipment Maintenance Schedule, active participation of employees in CIPAMIN and continuous use of Personal Protective Equipment.

INNOVATION

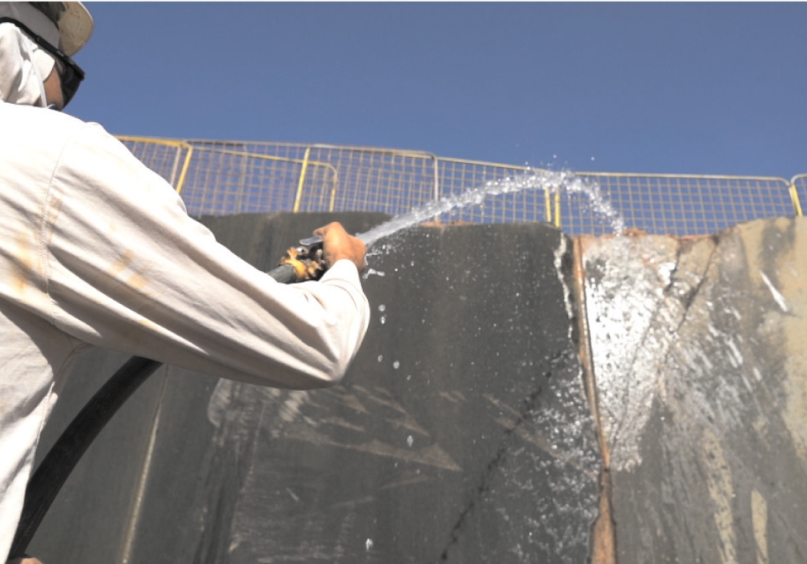

With the encouragement of management, creative mechanics observe the work environment every day and invent ingenious solutions, such as Silencers, which reduce noise during rock drilling, and Giraffes strong>, which prevent falling from height, as with them it is no longer necessary to climb onto the blocks to wet the stone cut.